We support the dental care that you are receiving through the manufacture and sale of dental materials.

Features and Strengths

Production of 100 million teeth per year – 2nd largest production capacity in the world

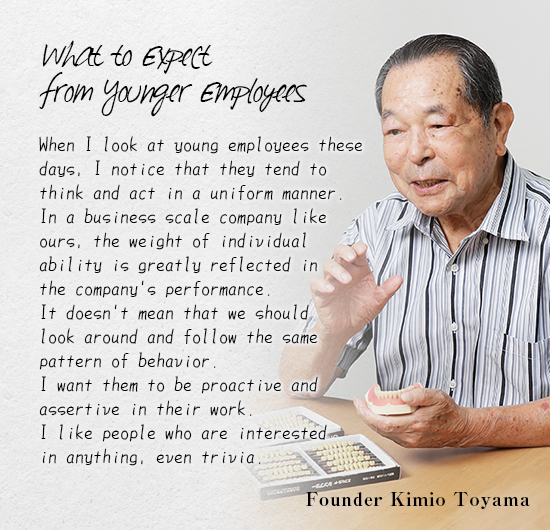

This figure symbolizes our company as a front runner among artificial tooth manufacturers. We produce over 100 million teeth per year and 26,000 different types of artificial teeth. There is no other dental manufacturer in the world that produces such a large volume and variety of artificial teeth. By pursuing production capacity and efficiency, and by maintaining a strict quality control system, we have been able to achieve excellent price competitiveness and high quality, in spite of the large variety of products. The root of our success lies in our “human resource development”. While promoting the introduction of equipment, we are also working to train and educate staff who can demonstrate their abilities.

This figure symbolizes our company as a front runner among artificial tooth manufacturers. We produce over 100 million teeth per year and 26,000 different types of artificial teeth. There is no other dental manufacturer in the world that produces such a large volume and variety of artificial teeth. By pursuing production capacity and efficiency, and by maintaining a strict quality control system, we have been able to achieve excellent price competitiveness and high quality, in spite of the large variety of products. The root of our success lies in our “human resource development”. While promoting the introduction of equipment, we are also working to train and educate staff who can demonstrate their abilities.

45 Vickers Hardness

The world hardest teeth with stain resistance

Our artificial teeth are known for being extremely hard and stain resistant. The Vickers hardness is 45, which is 1.5 to 2 times harder than the hardness of other artificial teeth available in the world. Our unique technology makes it possible to produce artificial teeth that are both the hardest in the world and the most stain resistant. This is the reason why our products have been so highly evaluated, including winning the Secretary of State for Science and Technology Award in 1999.

The world hardest teeth with stain resistance

Our artificial teeth are known for being extremely hard and stain resistant. The Vickers hardness is 45, which is 1.5 to 2 times harder than the hardness of other artificial teeth available in the world. Our unique technology makes it possible to produce artificial teeth that are both the hardest in the world and the most stain resistant. This is the reason why our products have been so highly evaluated, including winning the Secretary of State for Science and Technology Award in 1999.

Business experience with more than 90 countries

Aggressive global expansion

Our artificial teeth are supported by dental professionals all over the world due to their wide variety, competitive prices and high quality.

We have built fruitful partnerships with distributors in various countries, aimed at mutual development. Now our artificial teeth are sold in more than 90 countries around the world, and the brand name “YAMAHACHI” has grown to be recognized in overseas markets.

In 2020, we were selected as one of the top 100 global niche companies by the Ministry of Economy, Trade and Industry.

Aggressive global expansion

Our artificial teeth are supported by dental professionals all over the world due to their wide variety, competitive prices and high quality.

We have built fruitful partnerships with distributors in various countries, aimed at mutual development. Now our artificial teeth are sold in more than 90 countries around the world, and the brand name “YAMAHACHI” has grown to be recognized in overseas markets.

In 2020, we were selected as one of the top 100 global niche companies by the Ministry of Economy, Trade and Industry.

Making CAD/CAM cutting materials the second pillar of our business

In recent years, the use of CAD/CAM systems has risen rapidly in the dental industry, triggered by the acceptance of insurance coverage in Japan. We have been focusing on the usefulness of CAD/CAM since before insurance coverage was acceptable and have been developing products by applying our original technology cultivated through the development of artificial teeth. CADCAM cutting materials made of resin and wax have become the new core products of our company and our sales performance continues to expand both in Japan and overseas.

In recent years, the use of CAD/CAM systems has risen rapidly in the dental industry, triggered by the acceptance of insurance coverage in Japan. We have been focusing on the usefulness of CAD/CAM since before insurance coverage was acceptable and have been developing products by applying our original technology cultivated through the development of artificial teeth. CADCAM cutting materials made of resin and wax have become the new core products of our company and our sales performance continues to expand both in Japan and overseas.