- Category

- Synthetic Resin

BASIS PC

BASIS PC is a new semi-flexible thermoplastic injection resin base material.

BASIS PC is allergic reaction-free, odorless and easy to polish.

It is applicable for both full and partial dentures injection technique.

Features:

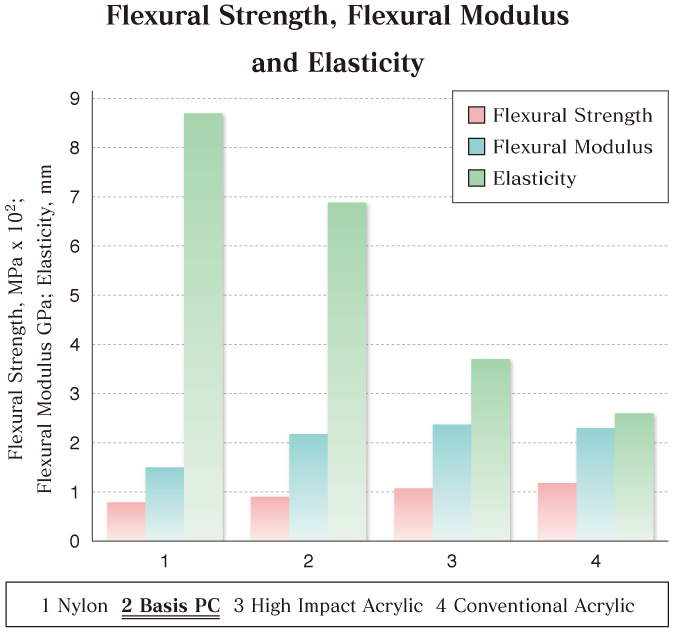

- Balanced Strength

Basis PC mediates the gap between Nylon and Acrylicʼs strength characteristics resulting in its exceptional and distinctive quality.

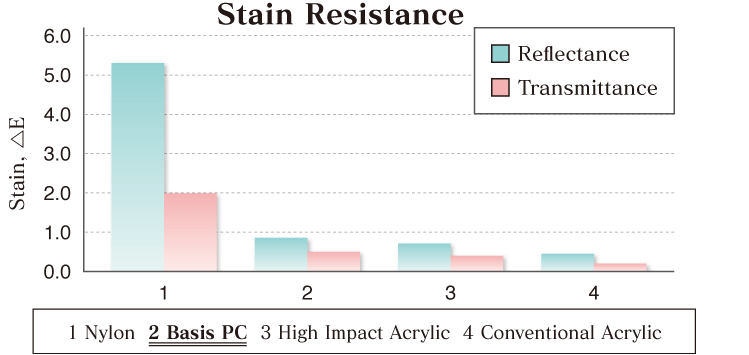

- Outstanding Stain Resistance

Basis PC effectively resists stain similar to that of acrylics.

High ΔE*(Reflectance) and ΔE*(Transmittance) of Nylon indicates ineffective surface stain resistance and penetration of stain into the material, respectively (*The larger the ΔE, the more susceptible material is to stains.)

- Superb Durability

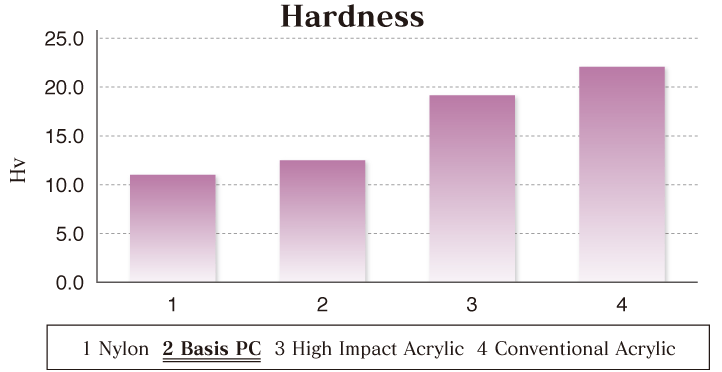

Basis PCʼs hardness is proximate to that level of Nylon.

Lower hardness, compared to acrylics, proves higher tenacity.

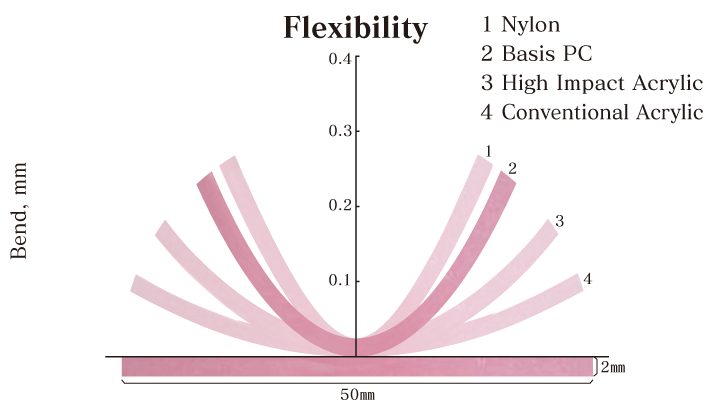

- Semi-Flexible

The concurrent proportion of Basis PCʼs strength characteristics gave rise to a new semi-flexible denture base material.

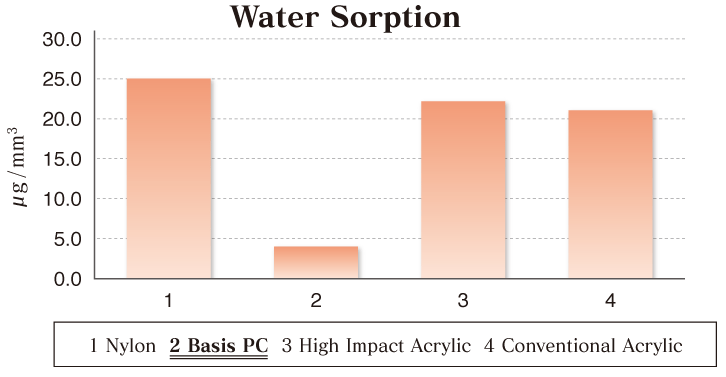

- Exceptional Water Sorption

Highly hydrophobic functionality resists water sorption.

Propagation of bacteria-causing odor is controlled.

Minimal deformation in intra-oral environment for long period of use is guaranteed.

- Repairable

Nylon No Basis PC Yes High Impact Acrylic Yes Conventional Acrylic Yes * Repair-ability using self-curing acrylic resin

| Packing | 1 kg |

|---|---|

| Shades |    |

| Accessory | Aluminum Tubes φ=2.5cm | ||||

|---|---|---|---|---|---|

| Type | Soft | Hard | |||

| Height(cm) | 10 | 4.4 | 7.8 | 8.5 | |

| Pellets Weight, g | 32 | 12 | 24 | 26 | |

Physical Properties

| Flexural Strength MPa | 96 | |

|---|---|---|

| Flexural Modulus, MPa | 2,076 | |

| Vickers Hardness, Hv | 12.6 | |

| Stain Resistance | Reflectance, △E | 0.8 |

| Transmittance, △E | 0.5 | |

| Elasticity(mm) | 0.5 | |

| Sorption, μg/mm3 | 5 | |

| Solubility, μg/mm3 | 0.1 | |

Injection Parameters:

Dry Basis PC pellets at 120℃ for 6-16hours before use;

Melting Temperature 305℃; Melting Time 25min.; Injection

Pressure 0.9MPa; Flask Temperature 90℃

Recent viewed products

No recent viewed